Introduction

What is CAS Number?

CAS Numbers, short for Chemical Abstracts Service numbers, are unique identifiers assigned to every chemical described in scientific literature. These numbers are crucial in scientific and industrial contexts as they provide an unambiguous way to identify substances, avoiding confusion that can arise from varied chemical names or formulas. Each CAS Number is distinct, enabling precise tracking and regulation of chemicals worldwide. This system is fundamental in ensuring safety, accurate communication, and consistency across industries such as pharmaceuticals, research, and manufacturing.

The Significance of CAS Numbers

-

Precise Identification: Each CAS Number uniquely identifies a single substance, eliminating confusion that can arise from similar or varied chemical names.

-

Enhanced Safety: They are integral to safety documentation, hazard communication, and regulatory compliance. CAS Numbers help quickly cross-reference safety data and regulations, streamlining communication between scientists, manufacturers, and regulatory bodies.

-

Facilitated Research: CAS Numbers allow for efficient access to comprehensive scientific literature, patents, and research information on specific substances. For organizations working across borders, the numbers ensure consistency in chemical identification, making research and development more accessible.

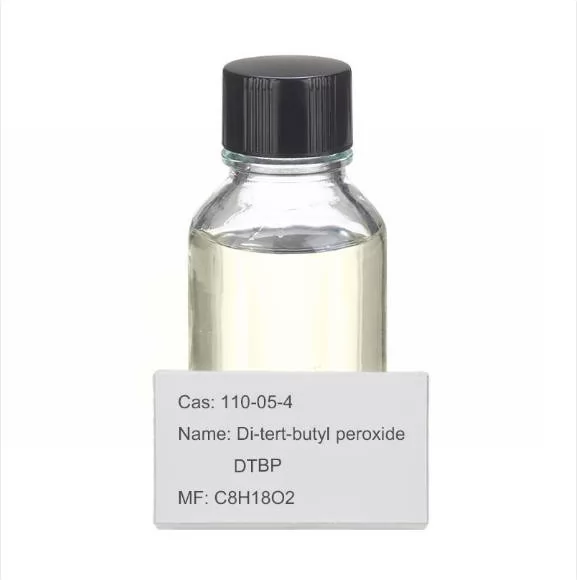

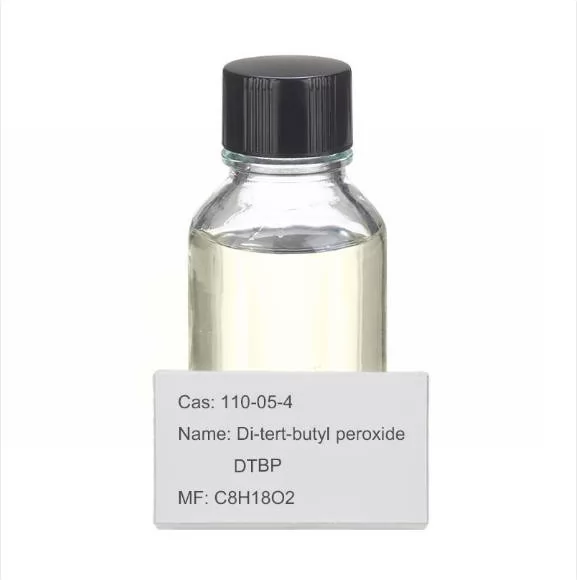

What is CAS Number 110-05-4?

CAS Number 110-05-4 identifies Di-tert-butyl peroxide,Di-tert-butyl peroxide or DTBP is an organic compound consisting of a peroxide group bonded to two tert-butyl groups. It is one of the most stable organic peroxides, due to the tert-butyl groups being bulky. It is a colorless liquid.

Properties of Di-tert-butyl peroxide

Chemical formula:C 8H18O2

Molar mass: 146.230g·mol-1

Density:0.796g/cm3 (25 °C)

Melting Point:-40 °C

Boiling Point:109 to 111 °C

Industrial Applications of Di-tert-butyl peroxide

-

Polymerization Initiator

-

DTBP is commonly used as a free radical initiator in the polymerization of monomers such as styrene and acrylic acid.

-

It plays a crucial role in the production of synthetic rubber, plastics, and resins, which are used in industries like automotive, construction, and packaging.

-

Crosslinking Agent

-

DTBP is used in crosslinking polyethylene, PVC, and other thermoplastics to improve their strength, flexibility, and durability.

-

This enhances the performance of materials used in electrical insulation, pipes, and cables.

-

Polymer Modification

-

DTBP is utilized to modify the structure and properties of polymers, such as altering the molecular weight or introducing new functional groups.

-

This is important for enhancing the material properties of plastics, coatings, and adhesives used in various industries.

-

Blowing Agent

-

DTBP acts as a blowing agent in the production of foamed materials like expanded polystyrene and polyurethane.

-

The gas produced during decomposition helps create lightweight, insulating, and shock-absorbing materials used in packaging and construction.

-

Organic Synthesis

-

DTBP is used in organic synthesis reactions to introduce oxygen atoms or create carbon-carbon bonds.

-

It serves as a key reagent in the production of various chemicals, including pharmaceuticals and agrochemicals.

Environmental and Safety Considerations in Production

-

Environmental Considerations

-

DTBP is a hazardous substance and should be handled with care to prevent environmental contamination.

-

It may release harmful gases if improperly disposed of, potentially causing air and water pollution.

-

Proper containment and neutralization methods should be in place during its production and disposal to minimize environmental impact.

-

Safety Considerations in Production

-

DTBP is highly reactive and can decompose violently under certain conditions, releasing heat and oxygen.

-

Safety measures include storing DTBP in cool, well-ventilated areas, away from sources of heat, light, and contaminants.

-

Workers handling DTBP must wear appropriate personal protective equipment (PPE), such as gloves, goggles, and protective clothing.

-

Special training is required for personnel to understand the risks and safe handling procedures when working with DTBP.

-

Fire and Explosion Risks

-

DTBP is highly flammable and can cause fires or explosions if exposed to ignition sources such as sparks or open flames.

-

It is essential to follow strict fire safety protocols, including the use of fire-resistant storage containers and automatic fire suppression systems.

-

In case of a fire, it is crucial to use appropriate extinguishing agents, such as dry chemical powder or carbon dioxide, and evacuate the area immediately.

-

Regulatory Compliance

-

DTBP production and usage must comply with national and international safety standards and environmental regulations.

-

Manufacturers must regularly monitor emissions and implement waste treatment protocols to ensure compliance with environmental protection laws.

-

Proper documentation and reporting of the quantities used, stored, and disposed of are essential for regulatory compliance.

How to Choose the Right Manufacturer?

-

Production Scale and Capacity;

-

Technical Strength and Expertise;

-

Product Purity and Quality;

-

Safety Data Sheets (SDS);

One outstanding option is High Mountain Chem, a professional industrial company specializing in the production of specialty chemicals, including Di-tert-butyl peroxide.

For further inquiries or to discuss your specific needs, feel free to contact our team.

Conclusion

Di-tert-butyl peroxide is an essential chemical used across various industries, including polymer production and chemical synthesis. Its role as a polymerization initiator and curing agent makes it vital for manufacturing synthetic materials used in many sectors. When sourcing Di-tert-butyl peroxide, it is important to consider product purity, safety standards, and supplier reliability. For your business needs, ensure you choose a manufacturer that adheres to industry regulations and provides high-quality products. Contact us for a free consultation to meet your specific requirements and ensure compliance with environmental and safety standards.