Products

Tert-Butyl peroxybenzoate (TBPB) an organic compound with the formula C6H5CO3CMe3 (Me = CH3). It is the most widely produced perester; it is an ester of peroxybenzoic acid (C6H5CO3H). It is often used as a radical initiator in polymerization reactions, such as the production of LDPE from ethylene, and for crosslinking, such as for unsaturated polyester resins.

HighMountainChem is proud to supply this compound, ensuring the highest quality for applications in coatings, adhesives, and composite material manufacturing.

TBPB, which is pale yellow, is exclusively encountered as a solution in solvents such as ethanol or phthalate.

As peroxo compound, TBPB contains about 8.16 wt% of active oxygen and has a self accelerating decomposition temperature (SADT) of about 60 °C. The SADT is the lowest temperature at which self-accelerating decomposition in the transport packaging can occur within a week, and which should not be exceeded while storage or transportation. TBPB should therefore be stored between minimum 10 °C (below solidification) and maximum 50 °C. Dilution with a high-boiling solvent increases the SADT. The half-life of TBPB, in which 50% of the peroxy ester is decomposed, is 10 hours at 104 °C, one hour at 124 °C and one minute at 165 °C. Amines, metal ions, strong acids and bases, as well as strong reducing and oxidizing agents accelerate the decomposition of TBPB even in low concentrations. However, TBPB is one of the safest peresters or organic peroxides in handling. The main decomposition products of tert-butyl peroxybenzoate are carbon dioxide, acetone, methane, tert-butanol, benzoic acid and benzene.

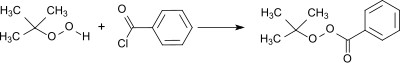

A standard procedure for the preparation of peresters is the acylation of tert-butyl hydroperoxide with benzoyl chloride. In the reaction a large excess of tert-butyl hydroperoxide is used and the hydrogen chloride formed is removed in vacuo whereby a virtually quantitative yield is obtained.

● In polymer chemistry

Primarily, TBPB is used as a radical initiator, either in the polymerization of e.g. ethylene (to LDPE), vinyl chloride, styrene or acrylic esters or as so-called unsaturated polyester resins (UP resins). The quantity used for the curing of UP resins is about 1-2%.

● In organic chemistry

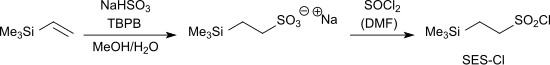

The protecting group 2-trimethylsilylethanesulfonyl chloride (SES-Cl) for primary and secondary amino groups is accessible by the reaction of vinyltrimethylsilane with sodium hydrogensulfite and TBPB to the sodium salt of trimethylsilylethanesulfonic acid and the subsequent reaction with thionyl chloride to the corresponding sulfonyl chloride.

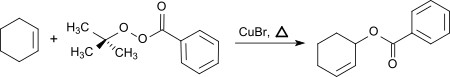

TBPB can be used to introduce a benzoyloxy group in the allyl position of unsaturated hydrocarbons.

From cyclohexene, 3-benzoyloxycyclohexene is formed with TBPB in the presence of catalytic amounts of copper(I)bromide in 71 to 80% yield.

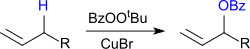

This allylic oxidation of alkenes, also known as Kharasch-Sosnovsky oxidation, generates racemic allylic benzoates in the presence of catalytic amounts of copper(I)bromide.

A modification of the reaction utilizes copper(II) trifluoromethanesulfonate as a catalyst and DBN or DBU as bases to achieve yields up to 80% in the reaction of acyclic olefins with TBPB to allylic benzoates.

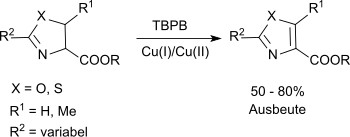

Substituted oxazolines and thiazolines can be oxidized to the corresponding oxazoles and thiazoles in a modified Kharash-Sosnovsky oxidation with TBPB and a mixture of Cu(I) and Cu(II) salts in suitable yields.

The carboalkoxy group at the C-4 position is essential a successful reaction.

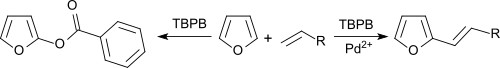

Benzene and furans can be alkenylated with olefins in an oxidative coupling under palladium salt catalysis, with TBPB as hydrogen acceptor.

In the absence of Pd2+ salts, the aromatics are benzoxylated.

Innovation at HighMountainChem includes exploring new applications for Tert-Butyl Benzoate Peroxide in biotechnology and advanced materials science. The compound's unique properties open up possibilities for developing novel materials and enhancing manufacturing techniques, contributing to advancements in sustainable materials and green chemistry solutions.

TBPB should be stored between 10°C and 50°C to avoid exceeding the self-accelerating decomposition temperature (60°C).

Container Requirements: Use chemical-resistant containers that are well-sealed to prevent leakage.

Ventilation: Ensure the storage area is well-ventilated to prevent gas accumulation. Incompatible Materials: Keep away from amines, metal ions, strong acids, bases, and strong reducing and oxidizing agents.

Spill Response: Absorb spills with inert materials in a well-ventilated area, and carefully collect and dispose of the material.

Fire Response: Use CO2, dry chemical, or foam extinguishers to fight fires; avoid using water. Skin Contact: Rinse the affected area with plenty of water immediately and remove contaminated clothing.

Eye Contact: Rinse eyes thoroughly with water for at least 15 minutes and seek medical attention immediately.

Inhalation: Move the affected person to fresh air and ensure they can breathe freely; administer artificial respiration if necessary and seek medical help.

Selecting HighMountainChem for your Tert-Butyl Benzoate Peroxide needs guarantees access to premium quality chemicals, expert support, and innovative solutions. Our commitment to quality, safety, and environmental sustainability ensures that we meet the evolving demands of the industry, providing our clients with reliable, efficient, and sustainable chemical products.

Partnering with HighMountainChem means you’re working with a leading supplier known for its dedication to excellence in chemical manufacturing. Our advanced production techniques, stringent quality control measures, and commitment to innovation place us at the forefront of supplying Tert-Butyl Benzoate Peroxide. Trust us to provide the high-quality products and solutions that will propel your projects to success.

The company has 20 years of extensive and deep knowledge and practice in the field of chemicals and international trade, and our products are under strict quality control. Each batch of products has undergone multiple tests to ensure stable and reliable product quality.

We can provide a full range of supply chain services, bundling and integrating comprehensive services to meet your unique needs. Trust us to create innovative solutions tailored to your business needs.

We have our own export team, import team, logistics team, technical department, and quality assurance and quality control, which can provide customers with professional technical support and solutions.

Deliver productivity in a way designed to dramatically increase your productivity and meet your needs and business goals by leveraging technology, using all modes of transportation, and managing the right partners.