Di-Tert-Butyl Peroxide, often abbreviated as DTBP, is a versatile chemical compound widely used in industrial applications. This organic peroxide is known for its ability to act as a powerful initiator in polymerization reactions, making it a crucial component in the production of various materials. But what exactly does it do, and why is it so important in different industries? Let's dive in.

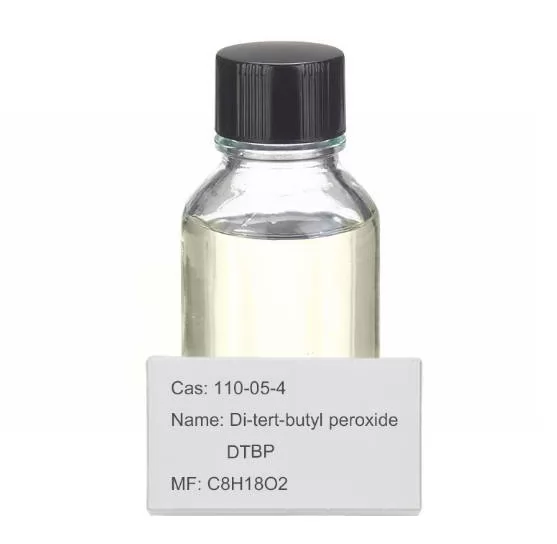

Before we get into the uses, it's essential to understand why Di-Tert-Butyl Peroxide is so effective. DTBP is a colorless liquid that decomposes into free radicals when exposed to heat. These radicals are highly reactive, which is why they are excellent at starting chemical reactions, especially in the polymerization process.

Di-Tert-Butyl Peroxide is used in various industries, but its most common application is in polymer chemistry. Here's a look at the key ways this compound is used:

DTBP is often used as a polymerization initiator in the production of plastics and resins. By generating free radicals, it helps start the chain reactions needed to form polymer molecules. This is critical in the manufacturing of products like PVC, polyurethanes, and certain rubber types.

DTBP is also used as a crosslinking agent. In this application, it helps improve the durability, elasticity, and resistance of rubber and plastic products. This makes it ideal for products that need to withstand high temperatures and pressure, such as tires and industrial gaskets.

Beyond polymer applications, Di-Tert-Butyl Peroxide is also utilized in organic synthesis. It serves as a reagent in the production of various chemicals and pharmaceuticals. Its ability to generate free radicals makes it useful in a range of reactions, including the production of ethers and alcohols.

DTBP is employed in curing processes, where it accelerates the hardening or solidification of various materials. This is especially relevant in the production of coatings, adhesives, and sealants. The compound's radical-producing properties help to speed up chemical reactions, ensuring the end product is strong and stable.

While Di-Tert-Butyl Peroxide is highly effective, it must be handled with care due to its reactive nature. Proper safety protocols should always be followed, including wearing protective gear and ensuring adequate ventilation in work environments. Always store it in a cool, dry place, away from heat sources, to prevent unwanted decomposition or explosions.

Superior Quality: We provide top-tier Di-Tert-Butyl Peroxide with high purity levels, ensuring it works efficiently as a polymerization initiator and crosslinking agent for your industrial applications.

Versatile Applications: Whether you're manufacturing PVC, polyurethanes, or other high-performance materials, our Di-Tert-Butyl Peroxide accelerates chemical reactions and enhances product strength and durability.

Safe and Reliable: Manufactured under stringent safety standards, High Mountain's Di-Tert-Butyl Peroxide meets industry regulations, ensuring safe handling and storage during your operations.

Global Reach: High Mountain's Di-Tert-Butyl Peroxide is trusted by manufacturers across various sectors, from automotive to construction, offering a reliable solution for your chemical processes.

Di-Tert-Butyl Peroxide is an indispensable chemical in several industrial applications, especially in polymerization and rubber manufacturing. Its ability to generate free radicals makes it a versatile tool for enhancing the quality and performance of products across various sectors. However, due care and attention are necessary when handling it to ensure safety and maximize its benefits.

Whether you're involved in the chemical industry, rubber manufacturing, or even the creation of specialty materials, understanding how Di-Tert-Butyl Peroxide works and its wide range of uses can help you optimize your processes and improve the quality of your products.